TechTalk #6: Die Strike

At Wilson, we’re always focused on the technical aspects of flexography. TechTalk is your quick snapshot of key topics in our industry. Let us know what you think.

Testing for proper die strike

Generally, the harder the strike is into the liner, the longer the tool will last. That’s why it’s essential to order a tool with the correct die strike. So how do you determine the depth of cut into the liner from hardest to lightest? It’s all in terminology. Here are the key terms we use to describe this important process.

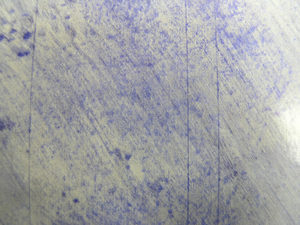

Hit HardThis is the strongest die strike There is a possibility of the liner being cut through. |

|

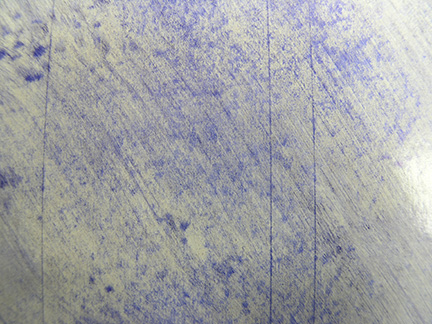

Hand Die StrikeThis will cut through the silicone layer on the liner in spots, but should not cause any blade to cut through the liner. |

|

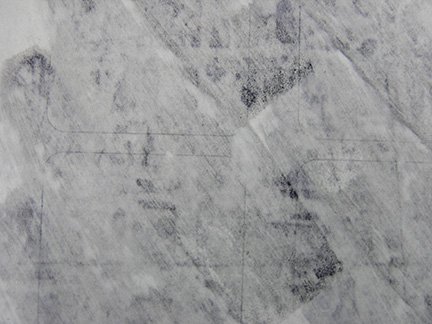

AutoThe Auto die strike will not cut through the silicone, but when the liner is colored, you’ll easily be able to see where the die is cutting. |

|

Super AutoThe Auto die strike will not cut through the silicone, but when the liner is colored, you’ll easily be able to see where the die is cutting. |

|

Checking for die strike

While there are multiple methods to check for die strike, the most common are Dykem or magic marker.

DykemDykem is a water-based method used to test any die strike. At Wilson, it is our typical test method. Because it is water based, it does not remove any of the silicone from the material. |

|

Magic MarkerThis method should only be used for Auto and Super Auto die strikes; any other method wil show extreme bleed. Because it is solvent based, some of the silicone is removed. |

|

Two Test Methods

We regularly use two testing techniques when determining peoper die strike: roll test and tensiometer application.

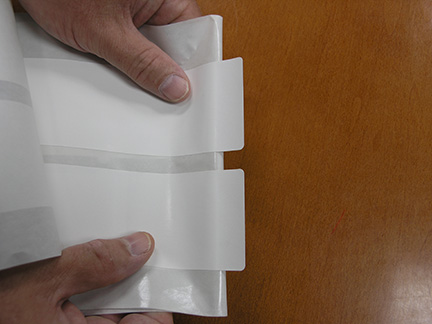

Roll TestThis method is sometimes used for Auto die strike. It’s achieved by pulling samples over a 90-degree corner to see if the leading edge of the label starts to dispense. You can also put a loop of material between finger and thumb and roll the material to check if the leading edge of the label starts to dispense. |

|

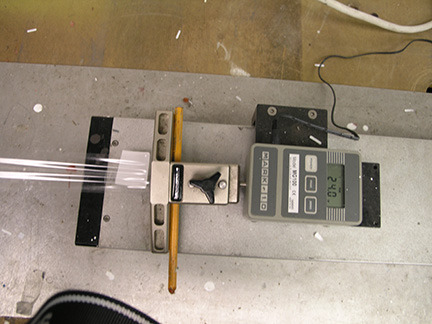

Tensiometer ApplicationThe proper way to test poly liners is to use a tensiometer. This machine measures the amount of force that can be put on the material before it deforms. We cut the samples into single lanes and stretch the material until it breaks or deforms. If it breaks prior to deforming, it fails the test. |

|

Ready to get started on your next project?

We’re here to help. Whether you know all the details of your job or need a little guidance, our team of professionals is ready to get to work for you.